A Perfect Staging Plan Means Never Having to Call Back

A client came to us needing a roof staging plan for their solar equipment. Simple enough, right? They had their proposed staging areas mapped out, a list of pallets and equipment specs, and knew where they wanted the crane. But here's the thing — we've done this before. A lot. And we could see their initial setup was going to need work.

Read more about our structural engineering services or our solar design and layout services

The Problem with "Close Enough"

Their proposed staging locations looked fine on paper. But in practice? Not quite. Some roof sections they hadn't considered might need to be used. The pallet count they'd estimated would probably fall short. And if we just built what they asked for and called it done, they'd be back in a few weeks asking for revisions. More time. More back-and-forth. More delays on an already tight schedule.

Not ideal for anyone.

Building in Flexibility from Day One

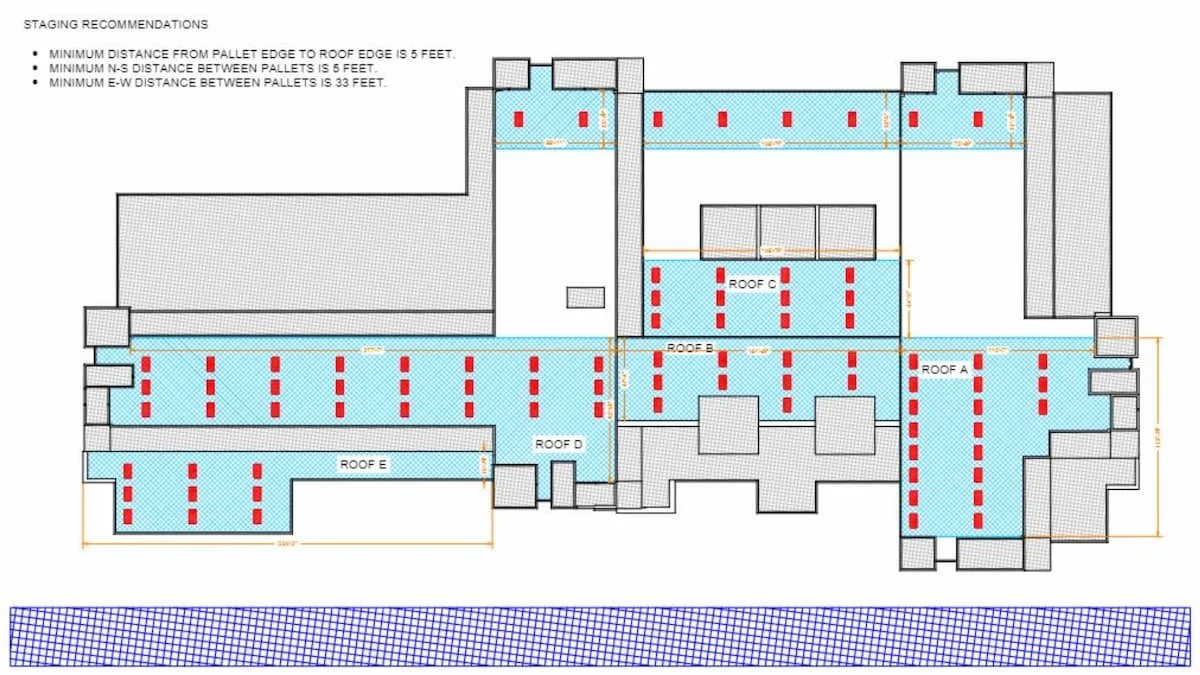

Instead of just executing their plan as-is, we designed something with room to breathe. Our staging plan included:

Extra pallet locations — because equipment counts always seem to grow, never shrink.

Additional roof staging options — more space if they needed it, without having to redesign the whole thing.

A clearly defined crane access path — so logistics could actually work on installation day (nothing worse than realizing the crane can't reach where it needs to go).

Standardized pallet spacing across all roof sections — keeps installation straightforward and consistent.

Maximum set weight per roof section — they could use any pallet weight within that limit without needing us to re-run calculations. One less thing to coordinate.

We delivered the plan on schedule. But more importantly, we delivered it with the kind of foresight that means they wouldn't need to come back for clarifications or changes.

What Actually Happened

The client got a staging plan they could actually use. No follow-up questions. No revision requests. No "hey, we actually need three more pallets, can you update this?"

They just moved forward.

That's the whole point, isn't it? When you're managing a solar installation, you don't need perfect documents. You need documents that work in the real world, where pallet counts change and roof sections get reassigned and nothing ever goes exactly according to the first plan.

Why This Matters

Look, anyone can draw up a staging plan that matches what a client asks for. That's not hard. What's harder (and more valuable) is recognizing where those initial assumptions might fall short and building in the flexibility to handle it before it becomes a problem.

We've seen too many projects get held up because the staging plan was too rigid. The client realizes they need adjustments. The engineer has to redo calculations. Timelines slip. Costs creep up.

Our approach eliminates most of that. You get a plan that adapts to the realities of installation without requiring constant revisions. It's not about being psychic — it's about experience. When you've worked on enough solar projects, you start to recognize patterns. You know where the pain points usually show up.

And you design around them.

Need a staging plan that actually accounts for real-world conditions? We've been doing this long enough to know where projects typically need flexibility. Let's talk about your next installation.